Category

- Bamboo Panels

- Natural Bamboo Panel

- Carbonized Bamboo Panels

- Horizontal Bamboo Sheet

- Vertical Bamboo Panel

- Cross Horizontal Bamboo Board

- Bamboo Furniture Board

- Bamboo Countertops

- Bamboo Worktops

- Bamboo Treads

- Bamboo Door

- Bamboo Wall

- Bamboo Blinds

- Bamboo Decking

- Woven Strand Bamboo Panels

- Stranel Woven Bamboo Flooring

35mm 50mm Bamboo Venetian Window Blinds Brushed Color with Anti-Mould Report

Overview Product Description Our Advantages Detailed Photos *** offer free samples Certifications *** more Certification

Basic Info

| Model NO. | BM002 |

| Usage | Living Room, Bedding Room, Bathroom, Office, Kitchen |

| Material | Wood |

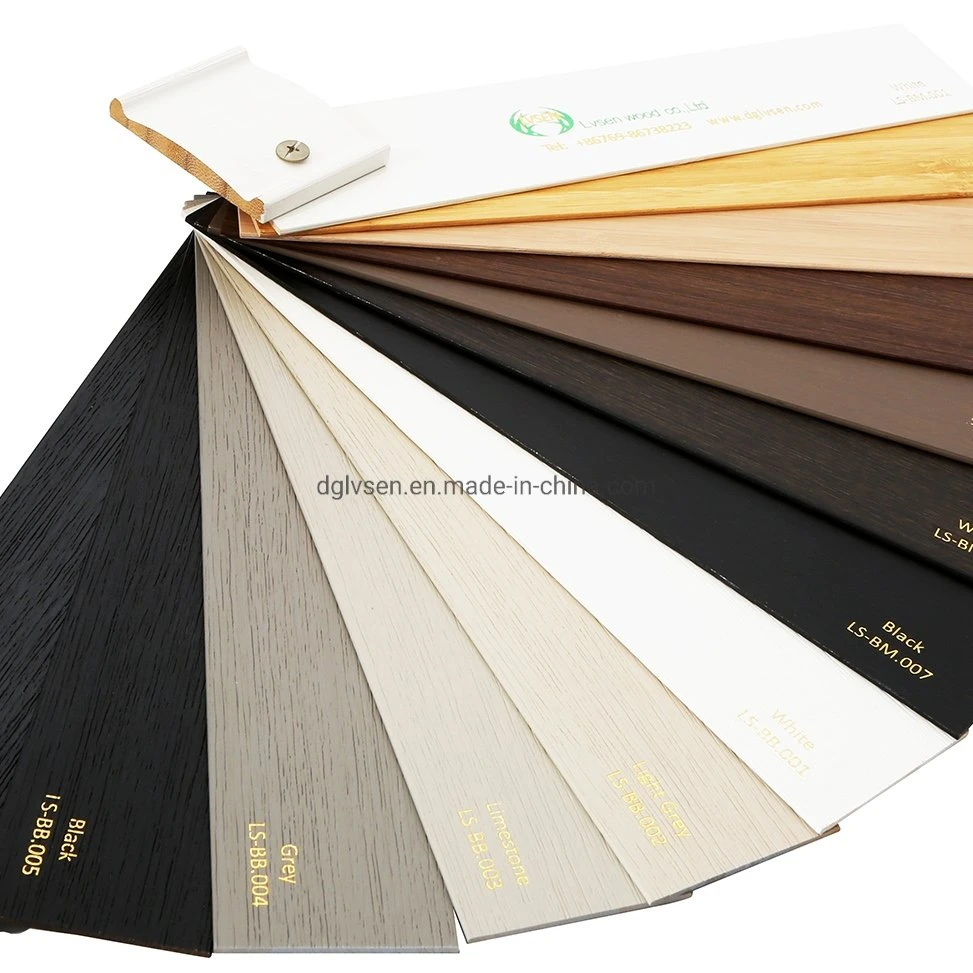

| Color | Customize |

| Function | Sound Insulation, Heat Insulation, Windproof |

| Customized | Customized |

| PCS/CTN | 100PCS/CTN |

| Glossy | 0~9 Degree |

| Paint | UV Paint |

| Finished | Stainded Color/ Plain Color |

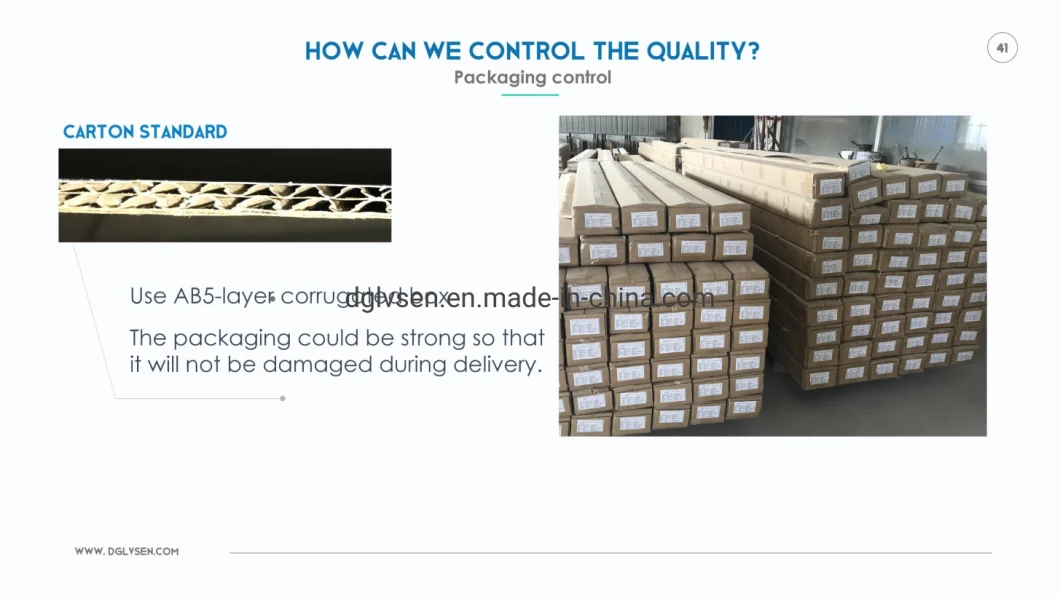

| Transport Package | Carton Box |

| Specification | 50mm*2.2+/-0.2mm |

| Trademark | no |

| Origin | China |

| HS Code | 4421999090 |

Product Description

| Products detail | |

| Material | from China |

| Width available in | 35mm, 50mm, 63mm, |

| Thick | 2.2mm+/-0.2mm |

| Length | Regular: 2.4mMax-length: 3.0mspecial need: 12ft (F.J) |

| Finished | UV-coating |

| Packaging | 100PCS/CTN |

| Specific Gravity | 680kg/m³ |

Our Advantages

| 1. Can be modeled with various natural wooden grains as solid wood has. It looks like solid wood and can be exquisite, noble, luxury, graceful, magnificent, elegant, color-riched, classic, modern, or Dando Shaft. |

| 2. Varnish-free, Nontoxic, harmless and truly green and environmentally friendly. |

| 3. Totally waterproof, can be used in bathroom. |

| 4. Strong surface hardness, wear-resistant, scuff-resistant (abrasion resistance is up to 3000 cycles). |

| 5. Non-deformed between -150ºC to 50ºC. |

| 6. Various shapes for all kinds of designs (especially in assembling baseboard, crown moulding, and border) |

| 7. Bright and smooth surface, easy clean |

| 8. Approved by National Quality Supervision and Examination Center of Fire Proof Building Material |

| 9. Possessed global patents in the production flow. One-piece forming, International leading technology. |

| 10. Current production process for the high polymer material is : the product was printed by colored pattern after extrusion, which will lead to unnatural and discontinuous pattern because the surface hardness is not strong enough. However, our company has adopted the One-piece technology and the surface hardness is strong enough (abrasion resistance is up to 3000 cycles) to manufacture various complexed patterns and natural grain, which has never peeled off and faded. |

| 11. No formaldehyde, crystallized under the molten condition. |

Detailed Photos

*** offer free samples

Certifications

*** more Certifications can be provided, please contact us~ thank you!

Production Process

Packaging & Shipping

FAQ

| Questions | Answers |

| Q1: Trading company or manufacturer? | We are a trading and manufacturer combination. Our factory established in 2002 more than 21 years experience. We have made foreign trade independent import and export rights ( H.S. code: 4421999090 ). There are 100 employees work in our factory. And our ability reaches 1,000,000 meters once a day. |

| Q2: What kind of products do you offer? | We deserve your TRUST because we focus on wooden slat and ready-made blinds. Material from Basswood, Marupa, WRC, bamboo and etc. |

| Q3: Does factory has its own brand? | Not yet. Welcome to tailor-made as your requirement. Please offer us your swatches and confirm the design details firstly. |

| Q4: How can you ensure your quality? | All of our items are strictly following this 4 step inspections. From natural wood to ready-made product, we control quality from the source. • Material Vendor Assessed • Incoming Materials Inspection • In-process Product 100% Check ( Inline inspection & Final inspection ) • Random Check after Final Packaging |

| Q5: Is the product tested by SGS, BV? | Sure. Firstly, we select raw material from the quality vendor. Secondly, paint vendor which have to include MSDS, and the paint must be tested by SGS, BV. Thirdly, our product also tested by SGS, BV. All of our products are strictly according to the testing standard. |

| Q6: What's your competitive advantage? Why should we choose you? | • Safety- More than 16 years experience professional in trading and manufacturing business domain, productivity reaches 100,000 meters per day, keep everything under your risk control.• Benefit- Focus on high quality with reasonable price and short leading time.• Happiness- Please be assured purchase because all of our products are strictly according to SGS, BV standard.• Convenient- Located at Dongguan City, Guangdong Province - nearby Shenzhen, Guangzhou, Taiwan, and HongKong, with great geographical advantages, ONE HOUR reach Shenzhen port, China. This is how we keep good quality and reliable cooperation for global valued customers. |

| Q7: What can we do for you? | • Response- Within 24 hours fast response to any inquiry.• Language - Our English server team will service you with all your special needs.• Server-Declaration, inspection, fumigation/disinfection, shipment, tracking after-sale service. |

Company Profile

Dongguan Lvsen wood co., Ltd. is founded in 2002. Our factory is located in Dongguan City, nearby Shenzhen, Guangzhou, Taiwan and HongKong, with great geographical advantages. We mainly produce Basswood, Marupa, WRC slat & Ready-made blinds. From natural wood to ready-made products, we do every process, it really a "Through-train" to the production. Our factory covers 25,000 square meters, we have 2 wooden storage plants, 12 drying kilns, 2 board-selecting workshops, 2 slat-selecting workshops, 4 UV and NC coating lines, we can produce 100 thousand meters coating slats per day. Ours produces up to SGS & BV standard, one hour reach Shenzhen port, this is how we keep good quality and reliable cooperation for global valued customers. Best quality and service is our principle to survival. To lead the company towards to a brilliant future, we treasure our customers both as business partners and as friends. We are willing to listen to your demands and advice to improve our products to make a better wooden life.